CNC FABRICATION

What is CNC Fabrication?

CNC stands for Computer Numeric Controlled, and refers to machines that have an automated output based on a digital design. This is sometimes referred to as digital fabrication. CNC machines are 21st century manufacturing tools that can work with a variety of materials such as metal, wood, and plastics.

CNC Fabrication can be used as stand-alone processes or integrated with our other Departments to create the desired object.

What are some benefits to CNC Fabrication?

The benefits to CNC Fabrication are: speed, accuracy, repetition, and ease of creating complex forms. Digital fabrication and CNC machines are versatile workhorses. 3D printers are additive machines that enable quick outputs of 3D designs. CNC machining tools are subtractive machines, cutting 2D or 3D objects in a variety of materials. The outputted object of either machine can be the final work, or used as a template, model, form, or mold for another process. Both types of machines excel with complex, hard to fabricate designs and with repetitive outputs. “If you can dream it, you can build it”.

What CNC/Digital Fabrication tools and capabilities do we have?

Our 1,100 square foot CNC Fabrication Department is outfitted with the following:

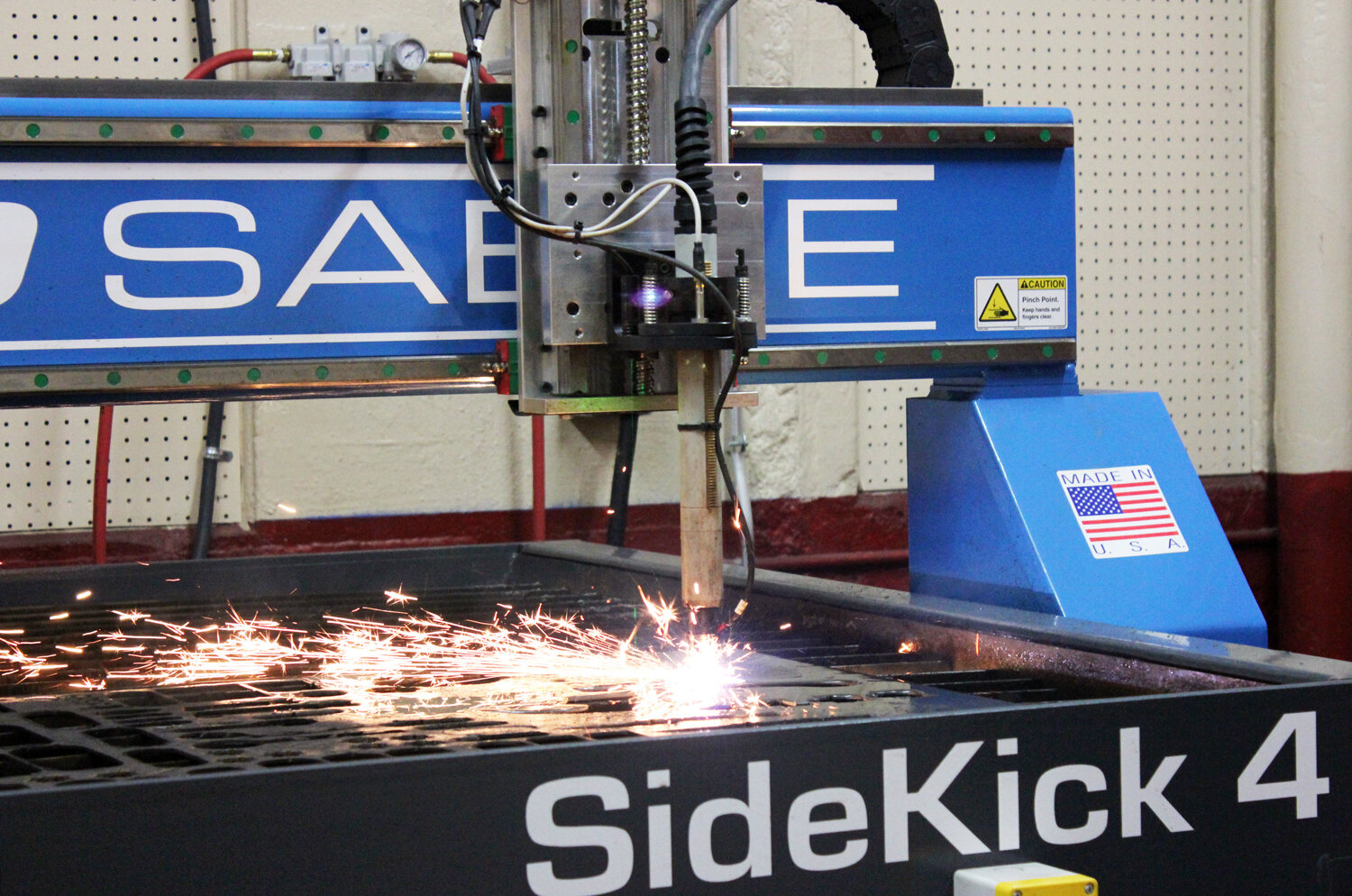

CNC Plasma Cutter and Engraver:

ShopSabre SideKick 4 CNC Plasma (52” x 49” 2D cut area)

Hypertherm PowerMax 65 Plasma Torch

Chicago Pneumatic Engraving Pen

Water Table

Materials Cut/Engraved: steel, stainless steel, aluminum, copper, brass, bronze

Maximum Cutting Thickness: 5/8”

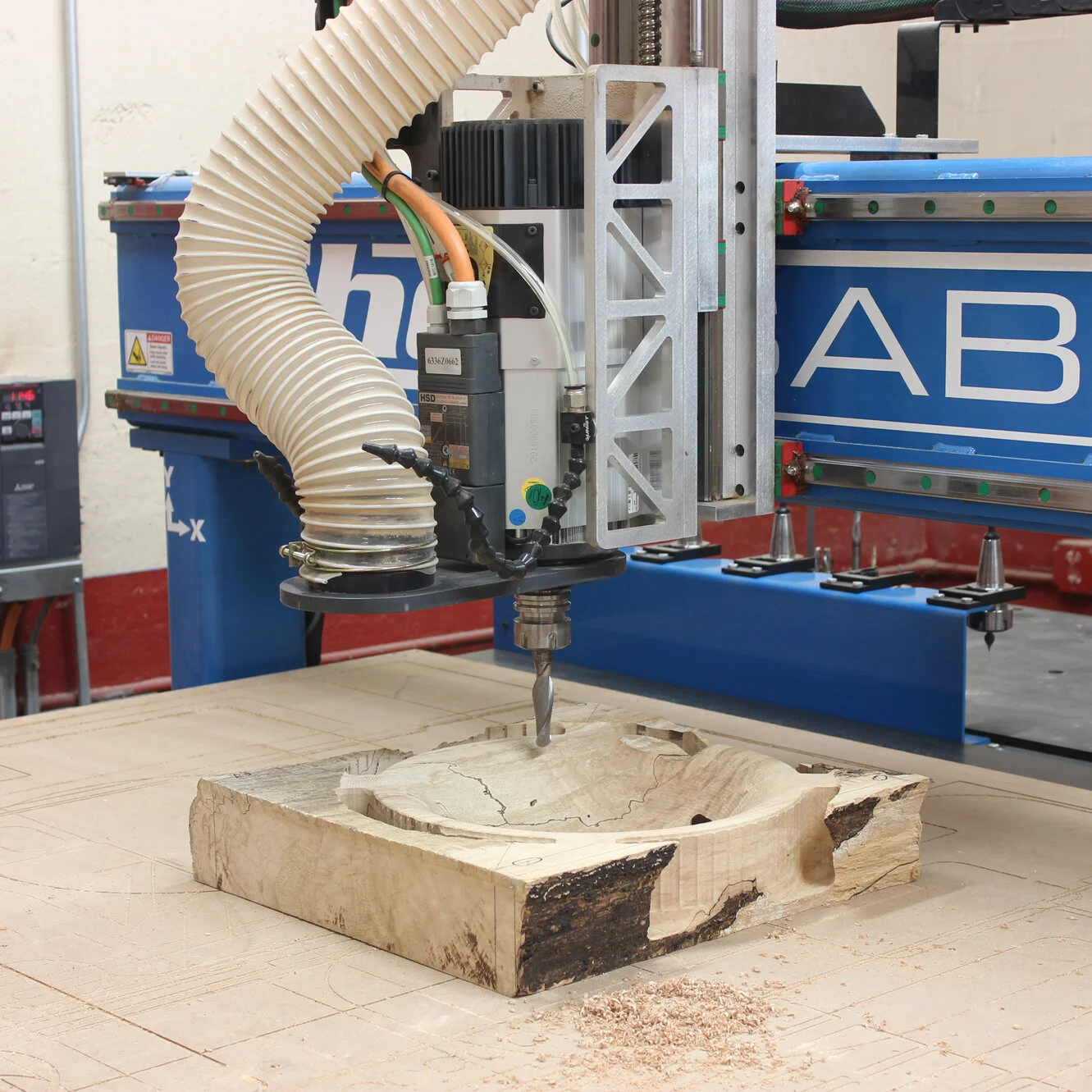

CNC Router:

ShopSabre Pro404 CNC Router (60" x 50" x 12" 2D, 2.5D, 3D cut volume)

4th Axis Rotary Indexer (6” swing)

Materials Cut: hardwood, softwood, plywood/sheet goods, carving foam, plastics, aluminum, brass

3D Printers:

Dremel DigiLab 3D45 Printer (10” x 6” x 7” build volume)

MakerGear M2 3D Filament Printer (8" x 10" x 8" build volume)

Materials Printed: ABS and PLA plastics

Printable File Formats: .stl, .obj, .3mf

Computer Workstations:

(6) PC-based Workstations

Vector-based and 3D Modeling Software: MeshMixer, V-Carve Pro, SolidWorks

CAM/Slicer Software: V-Carve Pro, Cura

Other:

Wood and metal finishing stations

Assortment of hand tools

Access to Metal Shop and Wood Shop during Class times, with Instructor Guidance

Material and Supplies offered for purchase in Department Shop

Storage for Material, Supplies, and Projects in Department Shop