As we begin preparing materials for the next Chicago Industrial Arts and Design Center exhibition Blueprints, CIADC office manager Danielle Euer has done some research on the origins of our building at Ravenswood and Schreiber:

"A reinforced concrete three-story and basement factory building 40 ft. high is now being constructed in Rogers Park, Ill., by laying out the walls on a horizontal platform resting on steel jacks, which raise the completed walls to a vertical position after the concrete has set. The building, which is 34 x 82 ft. in plan, is the first of a series of structures to be built by the Uno Manufacturing Company, which proposes to manufacture various toilet preparations that make a fireproof building desirable. To further this end, United States steel sash, tin-clad doors, concrete floors and partitions are used."

This description comes from the opening paragraph on page 352 of Volume 64, Number 13 of Engineering Record, printed in September 1911.

The building was constructed in 1910 by the Monolithic Concrete Construction Company, and Danielle informs us that "toilet preparations" as mentioned above was an early 20th century phrase used for what we would now call perfume. And or: "burnishing soaps, liquid and scouring soaps, silver and brass polishes, furniture polish, writing inks and disinfectants of all kinds," as per Hotel World of December 13, 1919. At any rate, we have cosmetic concerns to thank for the fireproof structure that is the 6433 North Ravenswood of today.

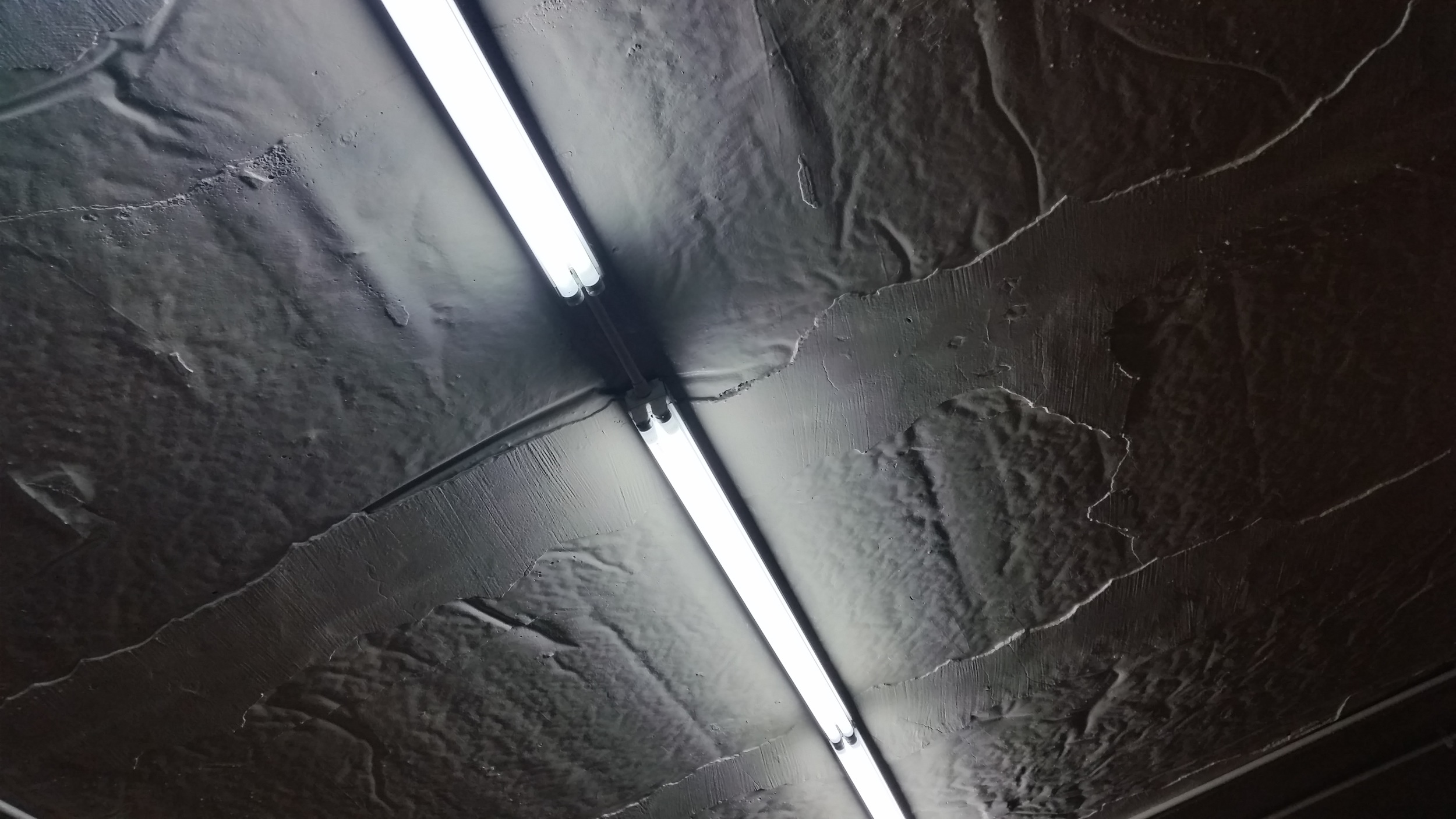

Further, the Record goes on to describe and depict the construction of the building in thorough detail. For example: "A unit floor system is to be used in which the lower 2 3/8 in. of the 6-in. floor is cast in 3 x 15-ft. slabs in the stock yard, one on top of the other with building paper between each slab."

One can see the evidence of the building paper on the ceilings throughout 6433 Ravenswood, as above. In the Universal Portland Cement Company Monthly Bulletin of February 1912, Monolith's flat-wall system for constructing the building is further discussed:

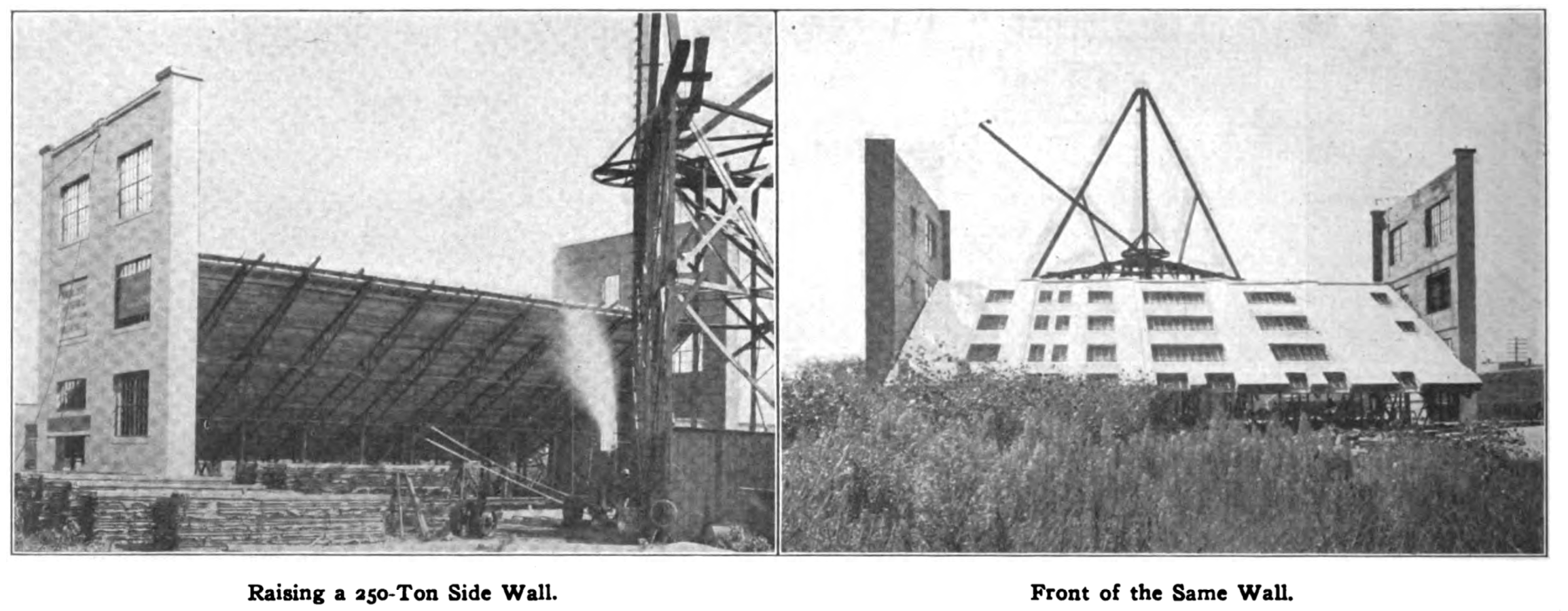

"The end walls were first erected and following this, the third wall, weighing about 250 tons, was raised, meeting the overlapping pilasters so perfectly that a slight amount of grout completed a perfect joint."

"The second view shows the platform almost completed for the last wall. Raising was accomplished by means of a five horse-power steam engine, shown at the right, through eleven jacks at about ten-foot centers, beneath the platform, and took but eight hours. It came to the exact final position within a small fraction of an inch."

Clearly, planning goes a long way. Check out the full details from Engineering Record and the Universal Bulletin for the whole story, and send us your own preparations and plans for the Blueprints exhibition, opening Saturday, May 21 at Chicago Industrial Arts and Design Center.

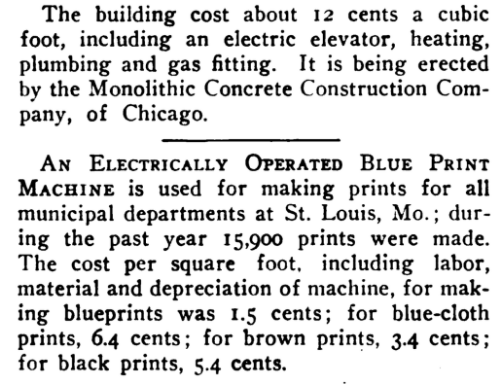

As a parting note, below is a nice confluence of subjects at the end of the Engineering Record article, with the construction costs of the building at 6433 listed directly above the cost of using an Electrically Operated Blue Print Machine in St. Louis, circa 1910: